Klinisk Biokemi i Norden · 1 2017

| 9

Verifying bias and imprecision

Measurement

bias

is a quantitative concept - the

“closeness of agreement between the average of an

infinite number of replicate measured quantity values

and a reference quantity value” (12).

Trueness

is the

corresponding qualitative concept for bias.

Measurement

precision

is a qualitative concept

- the “closeness between indications or measured

quantity values obtained by replicate measurements

on the same or similar objects under the specified

conditions of measurement” (12). The quantitative

expression of precision is

imprecision

- the standard

deviation (SD) or the relative standard deviation (CV/

CV %) of a method.

Method A can be qualitatively expressed to be more

or less precise than method B. But when you need

to quantify precision, we measure its opposite – the

imprecision – by repeated measurements of control-

or patient samples.

Measurement

accuracy

is a qualitative concept

describing the “closeness of agreement between a

measured quantity value and a true quantity value

of a measurand” (12). It encompasses both systematic

and random error components.

Verification practices have been established over

time and are frequently influenced by accredita-

tion- and certification authorities. There is by now a

general agreement on what is required (1, 9-11) and

supported by guidelines including CLSI EP15 (3) and

EP9(20). The European IVD directive (19, 21) requi-

res that the in vitro diagnostic device in the hands

of its end users must achieve the performance stated

by the manufacturer including analytical sensitivity,

limits of detection, diagnostic sensitivity, analytical

specificity, diagnostic specificity, accuracy, repeata-

bility, reproducibility and control of known relevant

interferences. In practice user verification is usually

restricted to comparison of methods experiments to

establish bias, replication experiments to establish

imprecision and a linearity check to determine the

reportable range and sometimes analysing reference

samples to verify the reference interval.

Estimating bias

At least 20 natural patient samples having as wide

concentration range as possible are commonly mea-

sured using both the method being replaced and the

new method. Stable materials for internal quality

control with known expected concentrations are also

measured to estimate imprecision and preferably also

appropriate reference materials as independent mea-

sures of bias. Larger number of samples than 20 may,

however, be required if minute differences between

the old and the new method need to be estimated.

The results of the measurements are summari-

zed using bias- Bland-Altman plot and orthogonal/

Deming regression as described below.

Estimating imprecision

Suitable stable materials for internal quality control

are measured at two concentration levels in at least 2

replicates for at least 5 consecutive days for estimating

imprecision and for establishing initial control limits

for the internal quality control procedures.

Summarizing the results

Orthogonal linear regression (22, 23), bias-plot (24, 25)

and analysis of variance (26, 27) techniques are used

to determine bias, imprecision, matrix effects etc. An

example is given

ysis of

20 patient samp

stems.

SigmaPlot 12.5 (

/

) was

used for the pur

alyse-

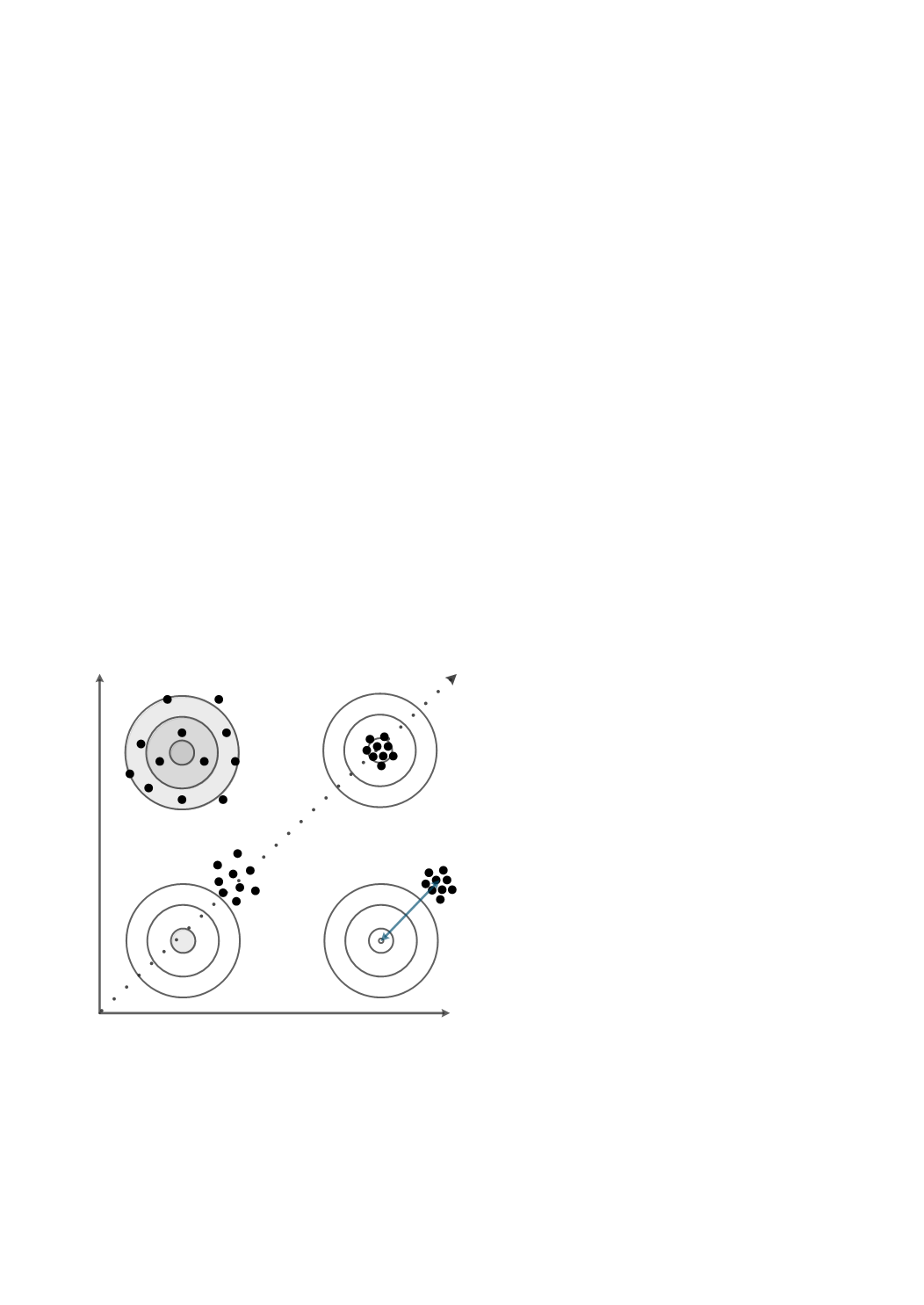

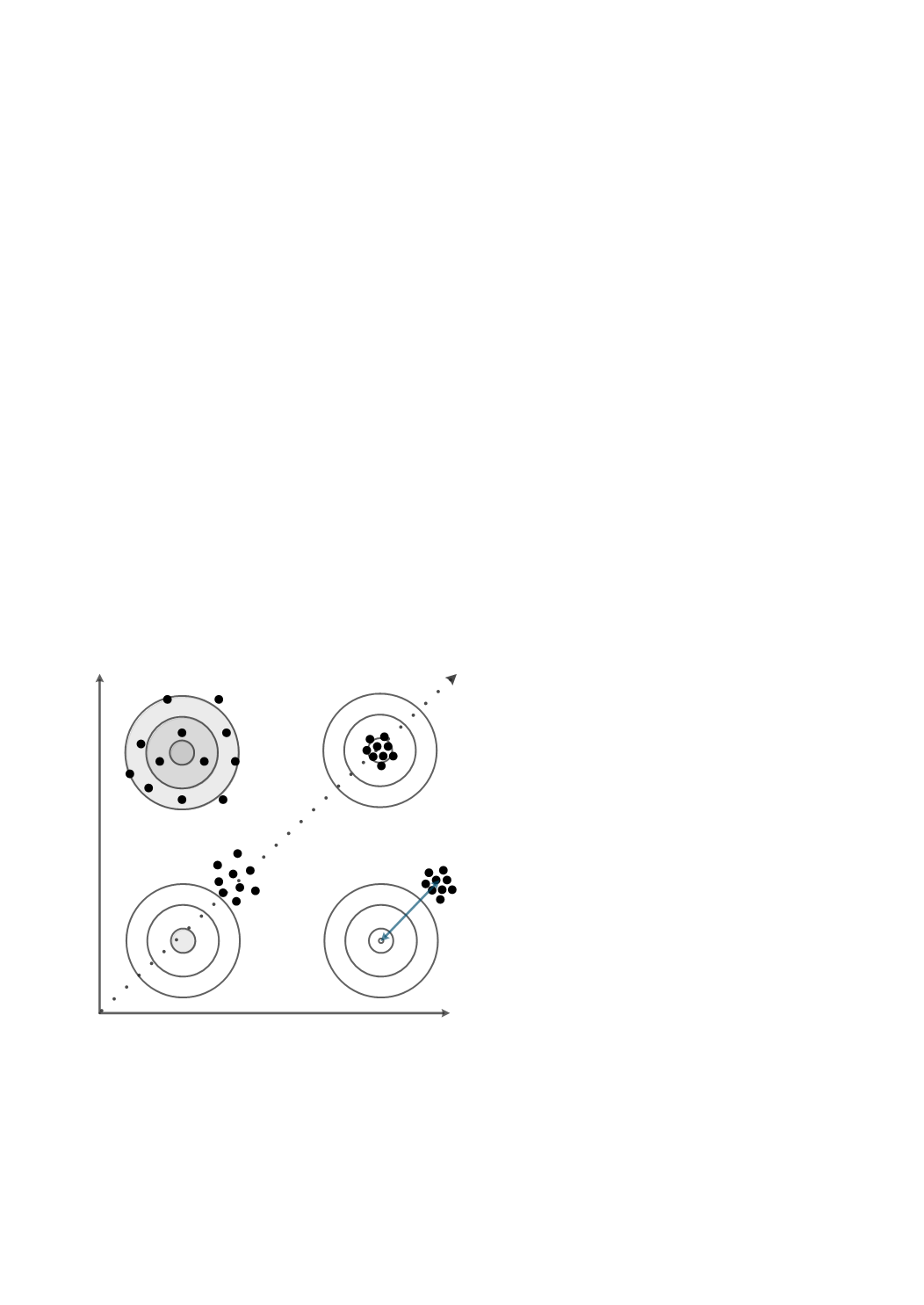

Figure 1:

A graphical illustration (using target analogy) of

the qualitative concepts precision and trueness and their

combination accuracy. Bias is decreased by increased tru-

eness and precision improved by decreasing imprecision.

Accuracy can be improved by improving precision or tru-

eness or both.

x

Improved precision

Improved trueness

Improved

accur acy

B ias