12 |

Klinisk Biokemi i Norden · 1 2017

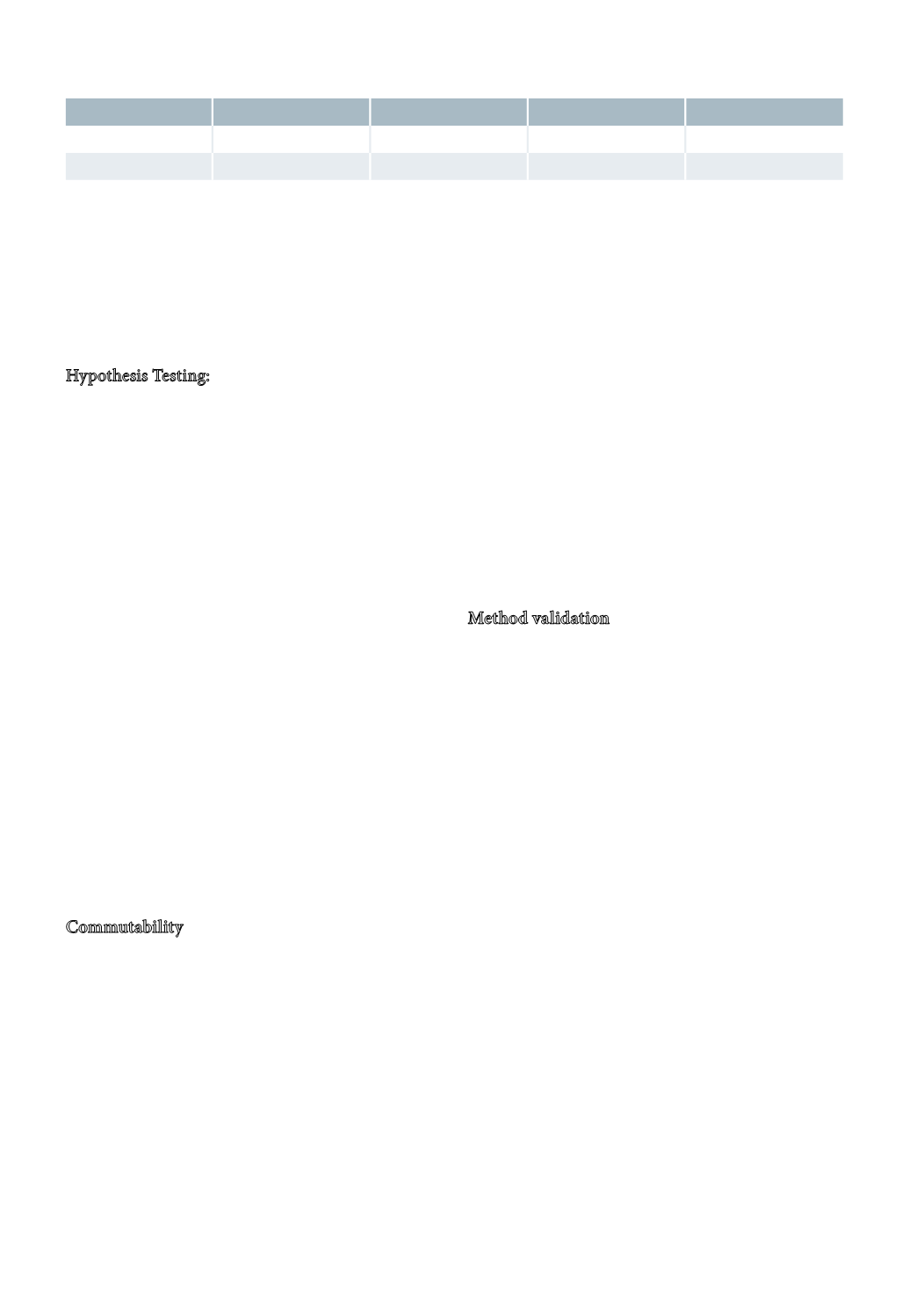

The standard deviation for each observation is only

known up to some common scaling factor. The stan-

dard errors for the parameters have been corrected

by an estimate of this factor, the square root of the

reduced chi-square.

Hypothesis Testing:

Test for slope = 0

F

= 5295,9198

P

= <0,0001

Test for slope = 1

F

= 2,8469

P

= 0,1088

Table 2

: The parameters of the ortogonal/Deming regression

as calculated by SigmaPlot 12.5.

Recalculating results

For the data above (tables 1 and 2) the slope of the

Deming regression line is 0,9683 and the intercept on

the Y-axis is 0,2688. This means that if you are mea-

suring samples for a study which extends in time over

the change of methods you will multiply the results

performed with the new method by 0,9683 and add

0,2688 in order to transform all results to the same

measurement level as the one which existed during

the time period of the old method.

Provided you wish to transform the results of the

old method to the results performed with the new

method you subtract 0,2688 from the results of the

old method and divide by 0,9683.

Commutability

Commutability is basically a characteristic of samples

which expresses their ability to result in very similar

measurement results using different measurement

systems. More formally it is a property of a material/

sample demonstrated by “the closeness of agreement

between the relation among the measurement results

for a stated quantity in this material, obtained accor-

ding to two given measurement procedures, and the

relation obtained among the measurement results

for other specified materials”. (31). Natural patient

samples are by definition commutable.

When comparing measurement methods during

verification and validation, it is crucial to include

natural patient samples as commutable materials in

a very substantial part of the the procedures in order

that the results ultimately measured in the patient

samples are comparable.

Medical laboratories process very substantial num-

ber of patient samples and have usually material to

spare that can be used for maintaining and increa-

sing the quality of the measurement methods used

in the laboratory. Medical laboratories therefore have

through the availability of patient samples a very

substantial advantage compared to the manufactu-

rers of measurement systems and methods when it

comes to the availability of patient samples in their

quality processes.

Method validation

Method validation (13, 16, 17) is commonly thought

of as a highly standardized single linear process, when

it actually consists of several dimensions of repetitive

sub-processes as depicted in figure 5.

In addition to the repetitive sub-processes for opti-

mation, there are a number of principally different

validation processes appropriate for the context that

the method(s) will be used in as follows.

Single laboratory method validation

Single laboratory method validation

is appropriate

when one method is used for a specific purpose in one

laboratory (13, 16, 17). This is the type of validation

provided by manufacturers to end-users.

Full method validation

Full method validation

in a conglomerate of labo-

ratories includes, in addition to the procedures of

single laboratory validation, a study of the fitness

for purpose of measurement systems in a number of

locations, several operators etc. including a study of

the performance characteristics of the measurement

systems over extended periods of time including the

effects of lot-to-lot variations etc.

Coefficient

Std. Error

95% Conf-L

95% Conf-U

Intercept

0,2688

0,0473

0,1693

0,3682

Slope

0,9683

0,0186

0,9293

1,0072